R&D Project Vibration Analysis

In an R&D project in cooperation with the university of Kassel,

TROUT GmbH is developing a system which, utilising a new and highly integrated signal processor and “Artificial Intelligence”, allows for intelligent and automated analysis and evaluation of rotating and/or accelerated components and/or systems.

Efficient maintenance has a big share in quality management and the avoidance of expensive idle times. By choosing the fitting maintenance strategy, 20-35% of idle time can be eliminated and maintenance cost can be lowered by 23%. The key to condition-based maintenance is systematic, precocious detection of malfunctions, using e.g. vibration analysis, to avoid total breakdown.

A highly integrated and miniaturised system is to be developed, displaying a multiplicity of possibilities of vibration analysis automatically. This includes the evaluation of bearings on rotating parts, of motors and gears for passenger cars up to electricity generating turbines and wind engines.

The system furthermore has to be flexible, concerning the wide appliance report, through automatic adjustment of all parameters. Statements concerning the actual condition as well as predictions for predictive maintenance and possible breakdowns (predictive exchange of components) are expected for the evaluation.

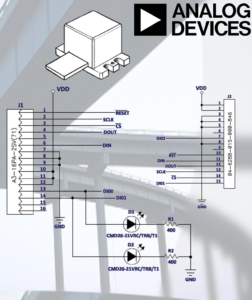

Only a highly integrated solution with a signal processor to control acceleration sensors with high accuracy in three axes as well as implemented signal preprocessing with Fast-Fourier-Transformation, communication of signals, processing of the signals with artificial intelligence and visualisation following predetermined requirements can accomplish all of the above mentioned.